PVP John Engineering

Houston, Texas USA

FFS ASSESSMENT

COMPLETED ASSESSMENT

COMPLETED ASSESSMENT

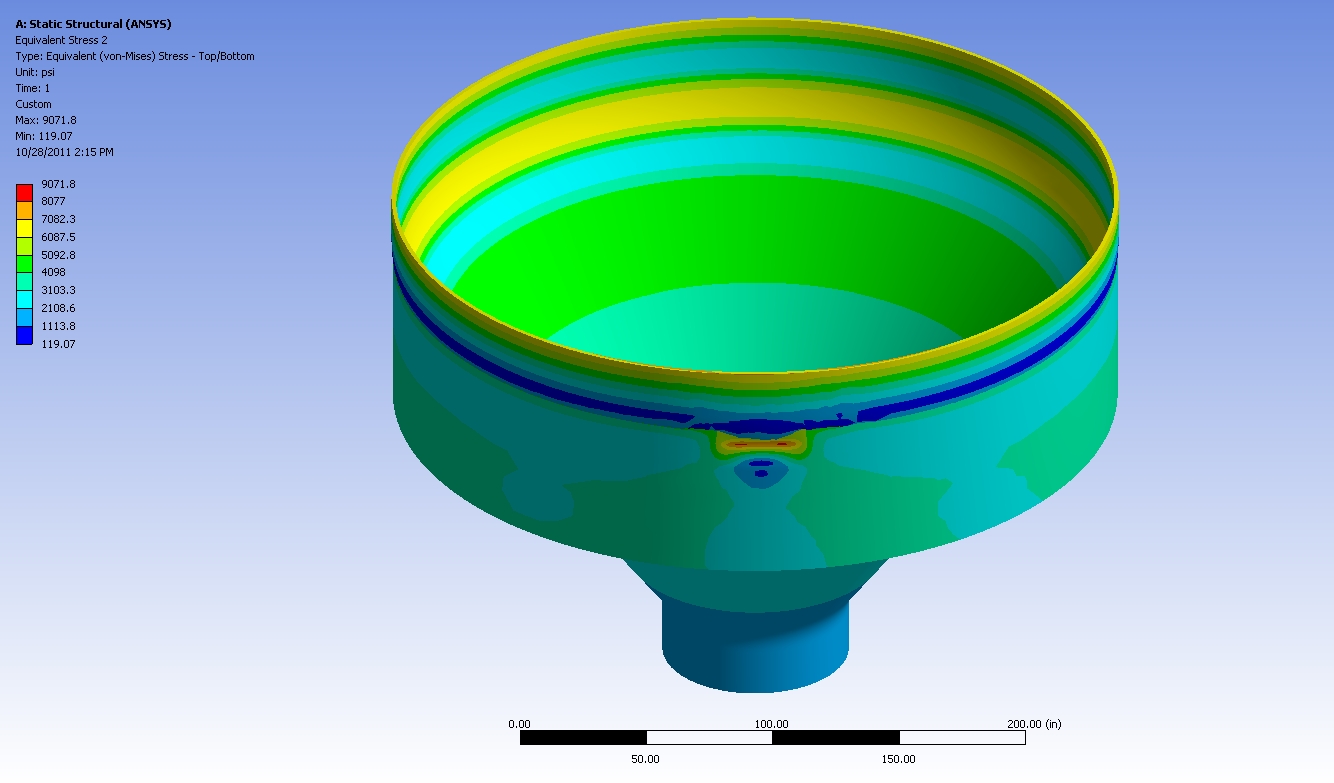

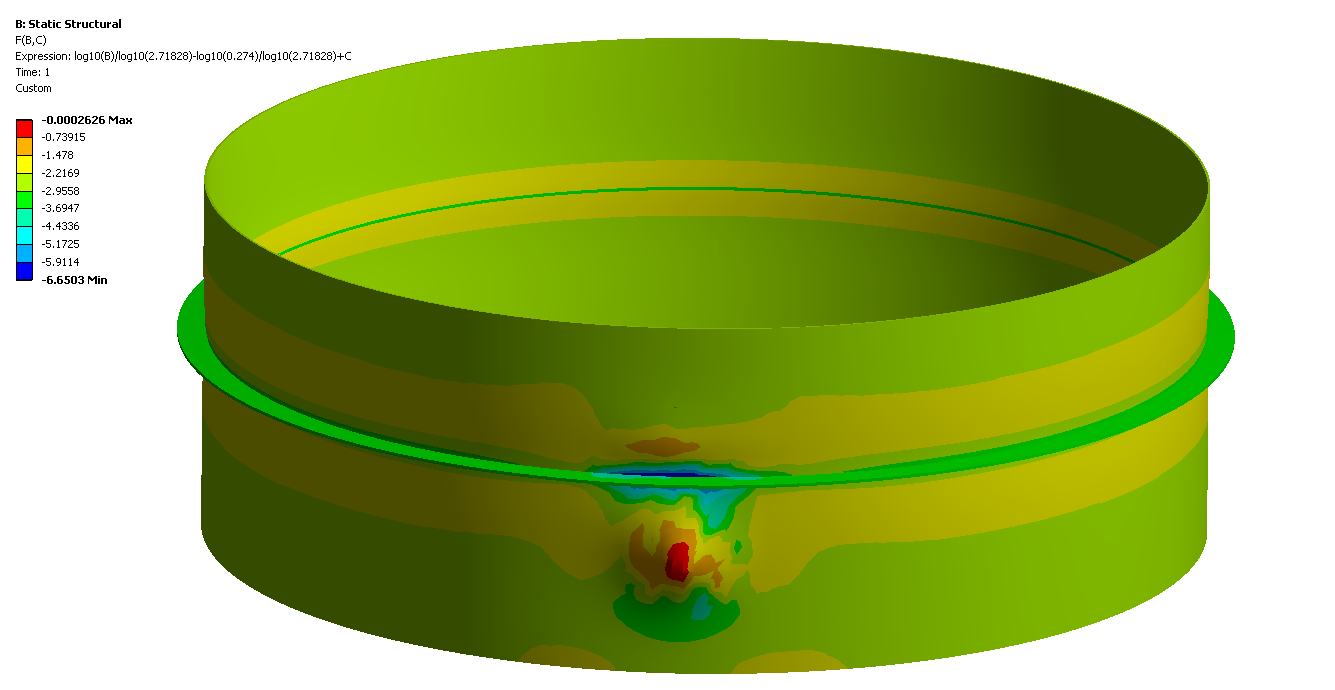

Level 3 FFS assessment to a local corrosion with a discontinuity crossing the area.

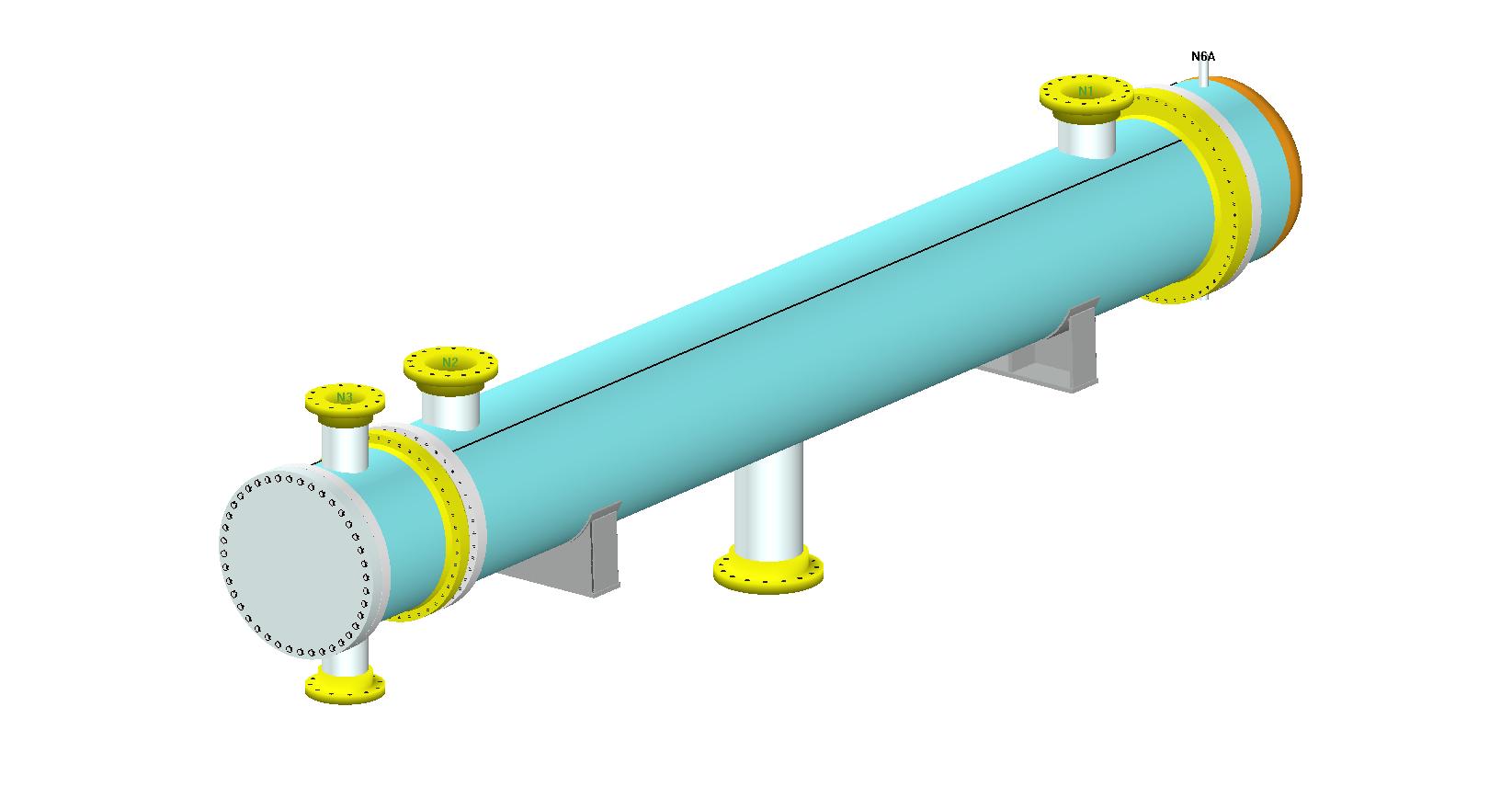

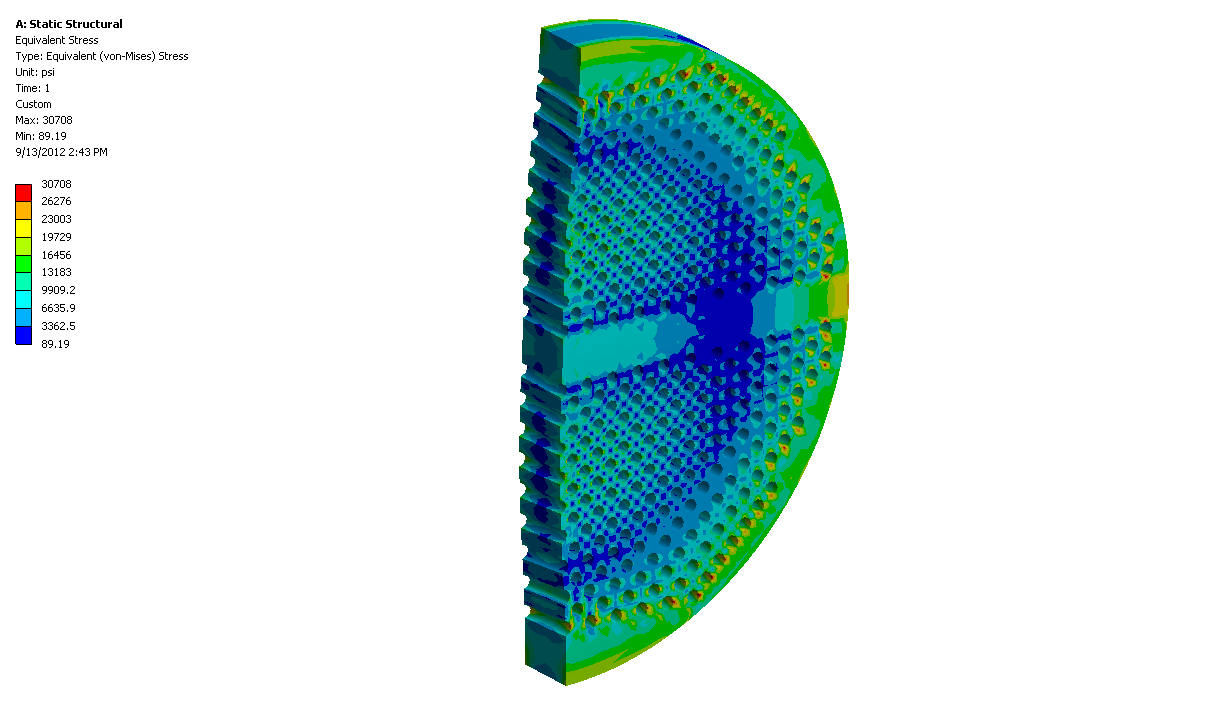

Tubesheet stress analysis under thermal load plus pressure excursion to 3 times of tubesheet design pressure.

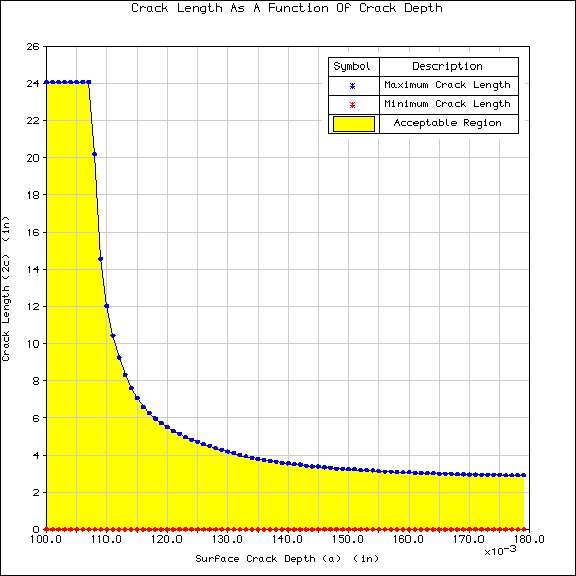

Crack size screening for a pressure vessel with cracks in hydrogen service.

Our Fitness for Service (FFS) assessment includes pressure vessels, reactors, pipelines and any other pressure containing equipment. We serve the oil refining, petro-chemical, chemical, power generation and pipeline industries.

Pressure vessels & piping engineering technical subject matter expert for the oil & gas and energy industries

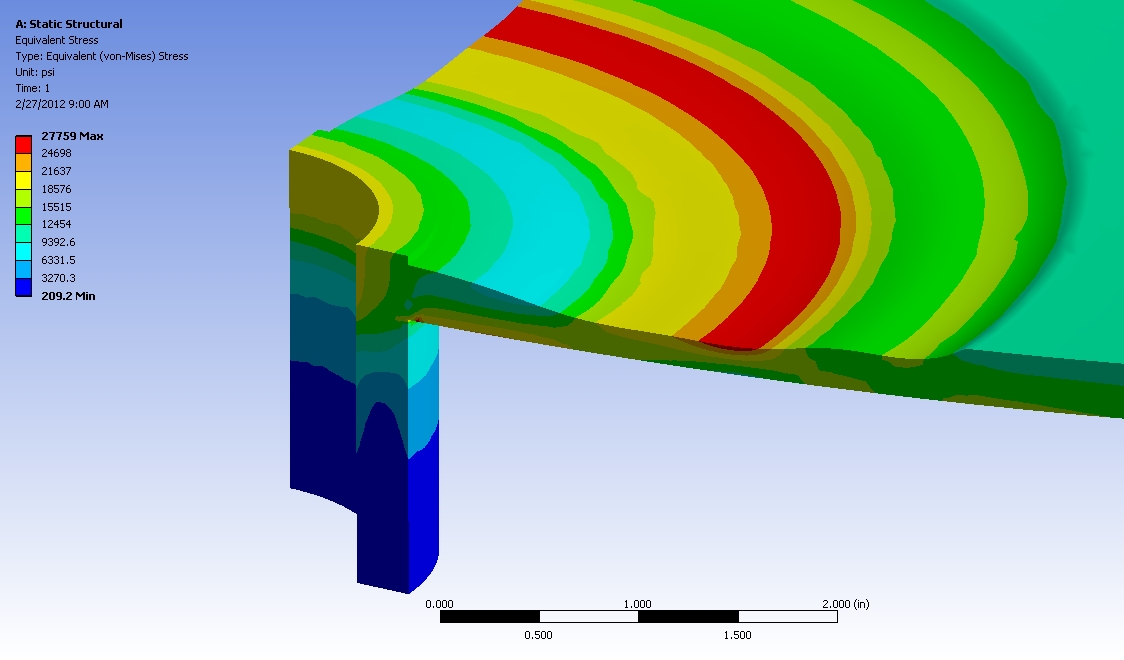

Stress analysis using FEA to an elbow connection failure to a weldolet.

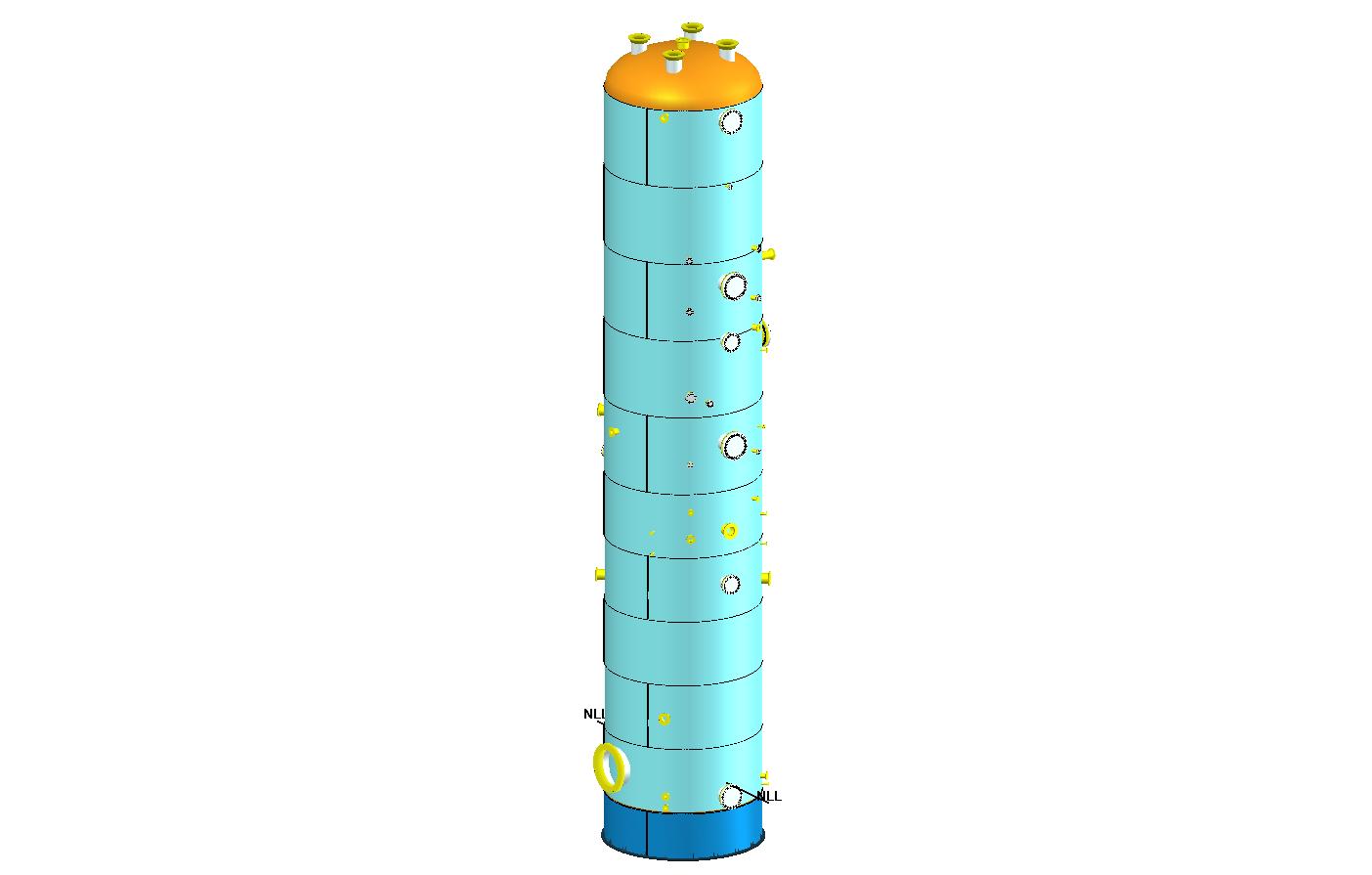

Design temperature rerate using COMPRESS for a main fractionator tower, which was built per API ASME code in 1938.

©2025-PVP Engineering

- API 579 level I, II and III.

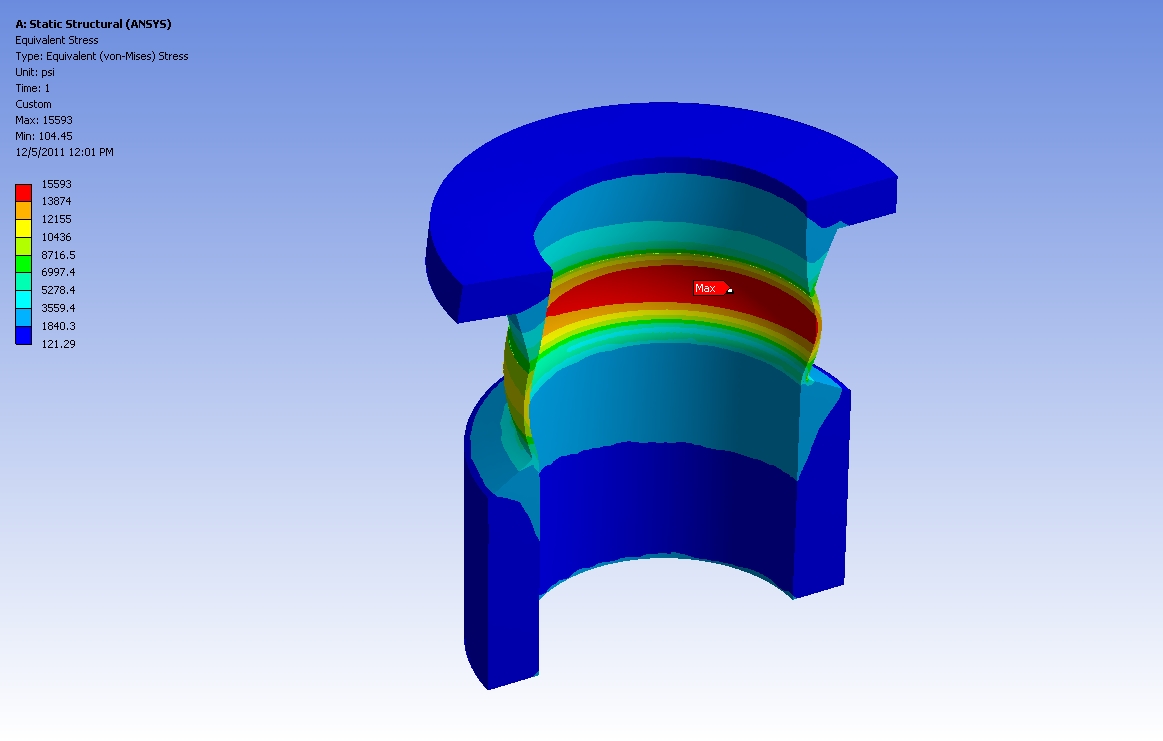

- Failure and Finite Element Analysis (FEA).

- Pressure vessel analysis and rerate.

- Life assessment evaluation.

- Pressure equipment shell thickness discard evaluation for petrochemical plant PCMS.

- Pressure equipment SDL assessment for pressure & temperature excursions.

Shell tube heat exchanger design temperature and pressure rerate due to processing requirement.

A level 3 FFS assessment for a local corrosion around a 12" bottom nozzle for hydrogen service.

A level 3 FFS assessment for local corrosion on a 24" forged nozzle of heat exchanger in HF service.

A level 1 & 2 FFS assessments for a locally corroded area on pressure vessel.

Roundness assessment for a vertical pressure vessel with local distortion.